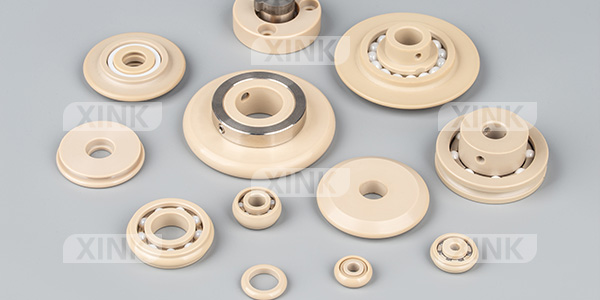

Wheel

Roller Style Material

| Common Materials | Mechanical properties/thermal properties | Electrical Characteristics |

| Polymer Polyethylene (UPE)(White) |

(a). The material is cheap. (b). Recommended operating temperature below 50 °C. (c). It has acid resistance. (d). The material is soft and the surface is easily scratched. (e). Processing size and stability are not easy to control. (f). It is more suitable for environmentally stable transport equipment. |

There is no antistatic or conductive properties, which may cause electrostatic effects when rubbed. (※ resistance value 1014 Ω or more) |

| Antistatic Polymer Polyethylene (Antistatic UPE)(Black) |

It has antistatic properties and has some conductive properties. It does not generate static electricity and does not leave static effects on the surface of the material. (※ resistance value 10M6 Ω~1011 Ω) |

|

| conductive polymer polyethylene (conductive UPE) (black) |

With antistatic properties, it also has excellent conductivity. If the material in contact with static electricity is available, it can be discharged when it contacts. And there is no residual electrostatic effect in the material. (※ resistance value 105 Ω or less, the device itself must be designed with a complete grounding function to allow the material to be electrostatically discharged) |

|

| Polyetheretherketone (PREK) |

(a). The price of the material is high. (b). Operating temperature up to 200 °C. (C). It has acid resistance. (d). The material has a high hardness and the surface is less likely to be scratched. (e). Processing size and stability are better. |

Non-conductor material. (※ resistance value 1014 Ω or more) |

|

Conductive polydextrose |

||

| Teflon (Teflon Teflon) |

(a). The price of the material is high. (b). Working temperature up to 200 ° C (C). It has acid resistance. (d). Has low friction characteristics. |

|

| stainless steel | (a). Suitable for high temperature baking equipment. | Conductor material. |

Select material focus:

- Select the appropriate material according to the working environment and the condition of the material to be transported.

- The roughness of the outer contact surface of the roller and the integrity of the outer circle.

- The straightness of the mandrel and the outer circle of the roller.

- The inner hole of the roller matches the tolerance of the outer diameter of the mandrel.

- Package and packaging.

Iron Ring Stop Roller

- The production process takes a short time and can be shipped 10 days after the order is received.

- Because the module is modularized because it contains stainless steel solid-locking iron ring, the outer diameter U+00D870 is higher due to the process factor; the outer diameter U+00D870 is lower because of the easier manufacturing process.

- The positioning method adopts stainless steel iron ring lock with fixed bolts, which is less prone to deformation due to thermal expansion and contraction.

- The positioning ring is made of stainless steel, and there is no material fatigue and deformation doubt, which is not easy to cause loosening or deformation.

| Retraction (left and right yaw) | Circular Run Out | |

| Wheel diameter U+00D8 50 or less | Within 0.03 mm | Within 0.03 mm |

| Wheel diameter U+00D850 or above | Within ±0.05 mm | Within ±0.05 mm |

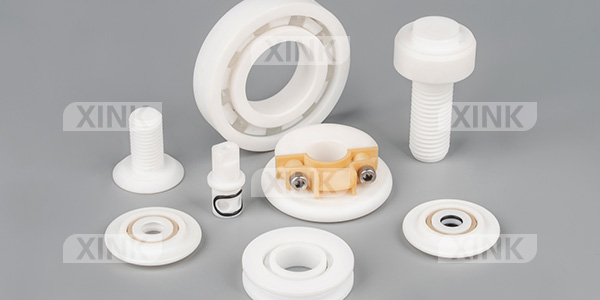

POM bundle ring wheel

- The production process takes a short time and can be shipped 10 days after the order is received.

- Outer diameter U+00D870 is lower due to process factors; when the outer diameter is U+00D870 or above, the process is not easy to be larger and the cost is higher.

- The roller and the mandrel are assembled and slid, and the wheel pitch can be finely adjusted due to equipment adjustment factors.

- Because the roller tightening ring is made of plastic steel material, the tightening ring may be fatigued and hardened due to environmental factors after long-term use, resulting in loose locking bolts or changes in roller spacing. Special care should be taken during maintenance.

| Retraction (left and right yaw) | Circular Run Out | |

| Wheel diameter U+00D8 50 or less | Within 0.07 mm | Within ± 0.05 mm |

| Wheel diameter U+00D8 50 or more | Within 0.1 mm | Within 0.075 mm |

Lineted combination wheel (Sleeve type)

Production Performance:

- The production process is generally available, and shipping can begin 15 days after the order is received.

- The lining positioning component is a daily product. If there is no stock, the delivery time will be limited by the time limit of the imported material. (about 45 days)

- The roller roller body and the inner lining ring kit are composed, which occupy less space.

- The inner liner kit is made of injection molding, the dimensional accuracy is not easy to control, and the inner liner kit is weak due to the thin design, so that the assembly and disassembly are not easy to control the roller spacing.

- Because the inner liner kit is made of plastic steel, it is easy to deform or loosen the roller due to external force or environmental influence. Pay special attention during maintenance.

| Retraction (left and right yaw) | Circular Run Out | |

| Wheel OD U+00D8 50 or less | Within 0.12 mm | Within 0.12 mm |

| Wheel outer diameter U+00D8 50 or more | Within 0.16 mm | Within 0.16 mm |

Quick Release Displacement Wheel

Production Performance:

- The production process takes a long time and can be shipped 15 days after the order is received.

- The roller is a 3-piece kit made of precision machining, so the cost is higher than that of the normal roller.

- The roller is designed to be locked by the inner ring after the nut is locked, and no additional tools are required for assembly.

- The roller spacing can be adjusted directly according to the condition of the equipment, without disassembling the parts.

| Retraction (left and right yaw) | Circular Run Out | |

| Wheel diameter U+00D8 50 or less | Within ± 0.05 mm | Within ± 0.05 mm |

| Wheel diameter U+00D850 or above | Within 0.08 mm | Within 0.08 mm |